|

Qingdao Rovan Machinery Co., Ltd.

|

high quality dust remover

| Price: | 2500.0~60000.0 USD |

| Payment Terms: | T/T,L/C, |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1. high quality dust remover

2. Certification:ISO9001

3. OEM is acceptable

4. Saving energy

5. Eco-friendly

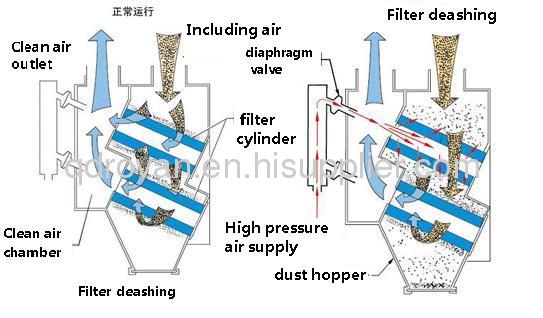

high quality dust remover principle of operation:

After dust-laden air enters the dust collector, due to sudden expanding airflow end and the role of air distribution plate, some of the large particle falls intohopper because of gravity and inertia; other small and tiny particle comes intofiltering chamber, then deposits on media's outer surfaces because of brownianmotion and fiber interception.

The clean air emerges into the cleaned air chamber and from there it is discharged. The resisstance of dust collector increases in accordance with expanding of dust concentration. When reaching a setpoint, the pulse valve of cleaning system jets a high speed&pressure airflow to clean the sut. That time PLC controls the open&close of the pulse valve.

While opening, the compressed air in packet enters theinner of filter cartridge equably, creates immediate pressure and great surge,and dislodges the dust layer falling into container.

high quality dust remover specification:

1. Applied advanced downflow design and cartridge horizotal insertable layout, in this way dust collector shows good performance in dust cleaning job.

2. Dust baffle plate setup in the dust-laden air intake, in the role of cushion and durable layer, approaches-avoidance of high speed impact to filter cartridge,thereby extend the life of them.

3. Cartridegs 15 C tilt drawer-style installation, enables more convenient remove. And no setup of transmission parts inside the dust collector, which meansmaxmimum cutting of maintenance cost. In terms of general dust, there can be noreplacement of filter cartridges for a lone time, in the case of saving burdensome work of frequently changing comparing with filter bags, and also a huge reduction of maintance costs.

4. Modular portfolio, the size of dust collector could be optional to cusotmers' requirement.

5. The size could be expaned on basis of existing portfolio by increasing dust removal unit, without many changes of original equipment.

Main model & specification of air filter, cartridge dust collector

high quality dust remover technical parameter:

high quality dust remover technical parameter:

Model | Cartridge Qty | Ait Velocity | Filtering area | Air volume |

HR3-12 | 12 | 0.4-0.8 m/min | 180 M2 | 4500-9000 |

HR4-16 | 16 | 0.4-0.8 m/min | 240 M2 | 6000-12000 |

HR3-24 | 24 | 0.4-0.8 m/min | 360 M2 | 9000-18000 |

HR4-32 | 32 | 0.4-0.8 m/min | 480 M2 | 12000-24000 |

HR4-48 | 48 | 0.4-0.8 m/min | 720 M2 | 18000-36000 |

HR4-64 | 64 | 0.4-0.8 m/min | 960 M2 | 24000-48000 |

Trade Terms:

- Payment:

1) Telegraphic Transfer (30% advance payment, balance before shipment)

2) Telegraphic Transfer (30% advance payment, balance against copy of documents)

3) Letter of Credit: at sight

2. Lead Time: 2 weeks after confirmed order

3. Delivery way: by sea

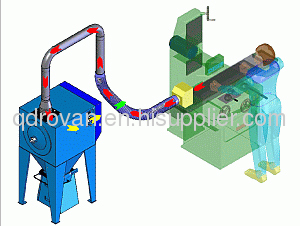

Application:

- Surface treatment

- Machined spare parts

- Style design

Our Service:

- Reply your inquiry in 24 working hours.

- Experienced staffs answer all your questions in fluent English.

- Customized design is available. UEM&UBM are welcomed.

- Exclusive and unique solution can be provided to our customer by our well-trained and professional engineers and staff.

- Special discount and protection of sales are provided to our distributor.

- Professional factory: We are manufacturer, specializing in producing all kinds of machinery for more than 11 years, competitive with good quantity.

- Sample: We can send out sample for test in one week if the order quantity is big enough. But the shipment charges are usually paid by your side, the charges will be rebounded when we have formal order.

- As an honest seller, we always use superior raw material, advanced machines, skilled technicians to ensure our products to be finished in high quality and stable feature. Welcome to contact us or visit our company.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Dust Remover

High Quality Bearing

High Quality Oil

High Quality Belts

High Quality Cameras

High Quality Faucet

More>>