|

Qingdao Rovan Machinery Co., Ltd.

|

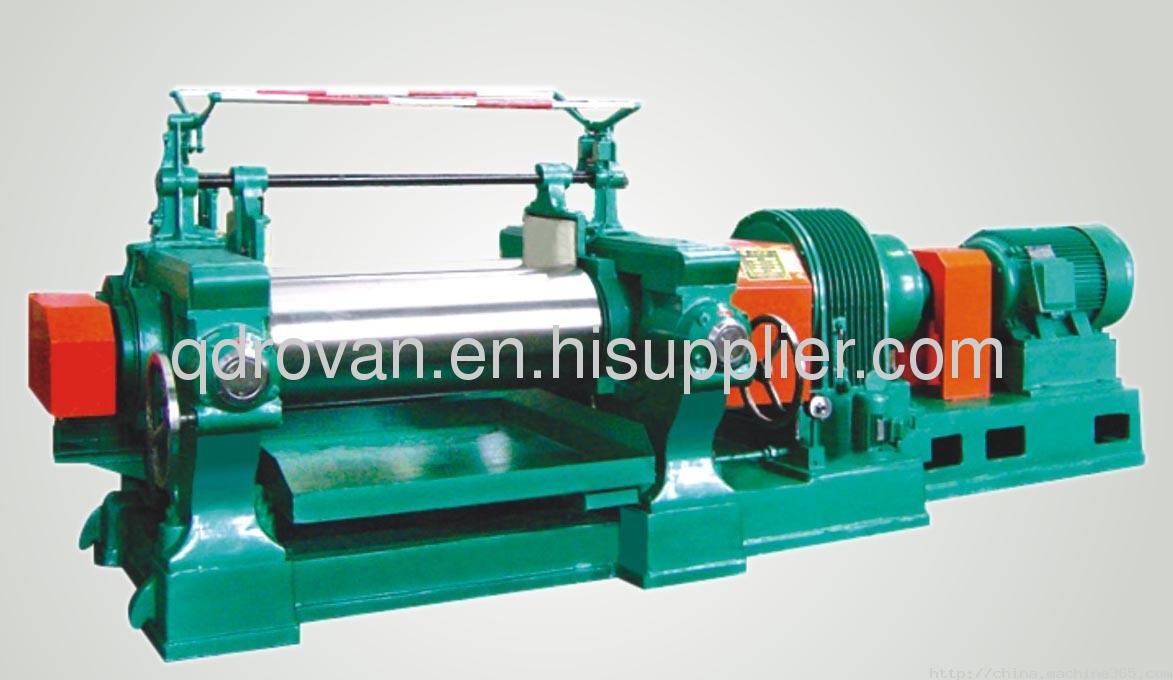

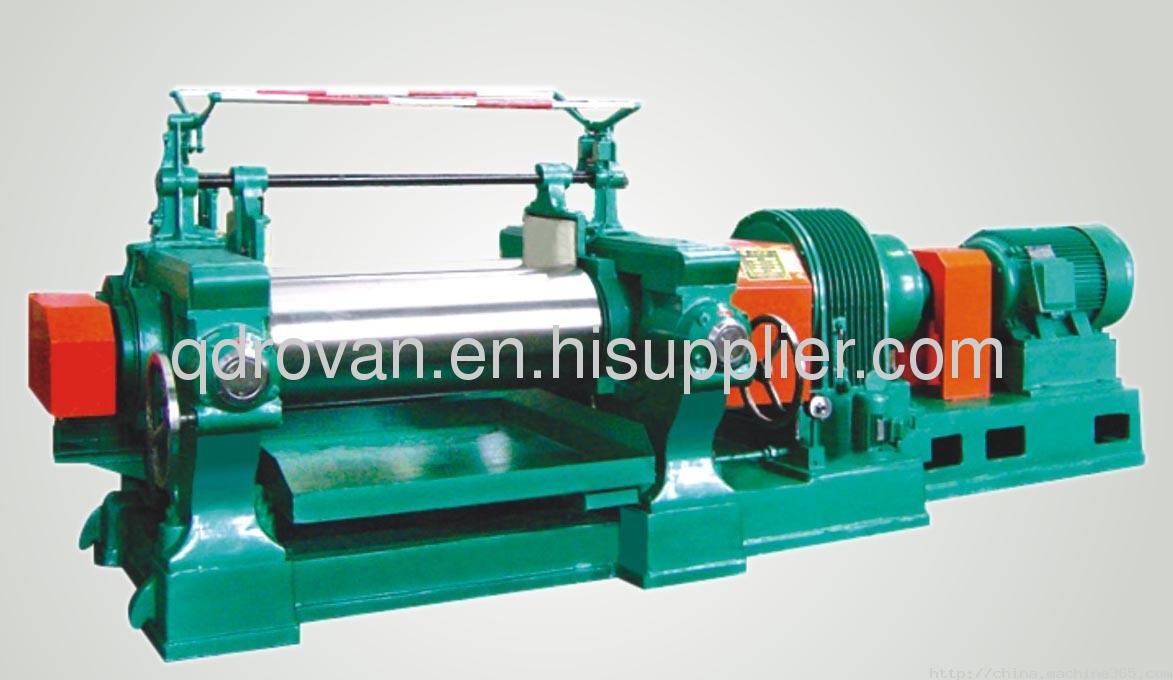

Open rubber mixing mill

| Price: | 2500.0~60000.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1. Certification:ISO9001

2. OEM: OEM service

3. Saving energy: Proper design

4. Automatic control: Eco-friendly

5.Open rubber mixing mill

1.Main Uses of Open Mixing Mill :

This machine is mainly used in Rubber & Plastic Product factory for Natural Rubber Mixing(plasticating),Raw Rubber and Compound mixing,rubber warm-up mixing and pressing sheet.

2.Structure of Rubber Mixing Mill:

Two Roll Mill consists of Base,Rack,Gland,Rollers,Bearing,Transmission device,Lubrication device,Decelerator,Adjustment device of the roller temperature,Emergency shutdown device and brake rigging and etc.

3.Features of Open Type Rubber Mixing Mill Rubber Machine:

A. The roll adopts the vanadium titanium metal alloy chilled cast iron and its surface is hard and wear-proof. The internal cavity is processed to make temperature well proportioned on the roll surface.tailored structure, easy to operate.

B. The machine is equipped with an overload protection device to prevent the main components from being damaged.

C. The machine is also equipped with an emergency brake device. When an emergent arises, just draw the safety pull rod, and the machine will stop immediately. It is safe and reliable.

D. The transmission system adopts a hardened tooth-surface reducer, which has a compact structure with higher transmission efficiency, lower noise and longer service life.

E. The base frame is a whole framework, which is convenient for installation.

F. Stock bender for direct rubber sheet and knife to cut as your need to assemble.

G. Auto-lubrication sysytem for greese or oil and match bearing bush.

H.There are many speeds and speed ratios available, which can satisfy most customers' formula and processing requirements.

i.Frame, frame cap and base, looking very nice, are welded and treated by annealing for stress relieving.

Model item | XK-160 | XK-250 | XK-360 | XK-400 | XK-450 | XK-550 | XK-560 | XK-660 | XK-710 | ||

Roll diameter | mm | 160 | 250 | 360 | 400 | 450 | 550 | 560-510 | 660 | 710 | |

Roll working length | 320 | 620 | 900 | 1000 | 1200 | 1500 | 1530 | 2130 | 2200 | ||

Front roll linear speed | r/min | 9 | 16.3 | 16.7 | 19.3 | 21.8 | 22.5 | 27.2 | 28 | 31.9 | |

Speed ratio of rolls | 1:1.35 | 1:1.1 | 1:1.25 | 1:1.27 | 1:1.27 | 1:1.2 | 1:1.2 | 1:1.24 | 1:1.51 | ||

Max roll space | mm | 4.5 | 8 | 10 | 10 | 12 | 16 | 15 | 0.5-15 | 0.5-15 | |

Compound feeding capacity | kg | 1-2 | 10-15 | 20-25 | 18-35 | 50 | 50-65 | 50-65 | 165 | 190 | |

Motor power | kw | 5.5 | 18.5 | 30 | 45 | 55 | 110 | 90 | 240 | 280 | |

Dimensions L*W*H | L | mm | 1133 | 2722 | 4200 | 4920 | 5405 | 6646 | 6270 | 7280 | 8185 |

W | mm | 920 | 1115 | 1780 | 1780 | 1740 | 2736 | 2282 | 3400 | 3910 | |

H | mm | 1394 | 1345 | 1760 | 1800 | 1790 | 2105 | 2000 | 2530 | 2270 | |

Gross weight | t | ~2 | ~3.2 | ~6.5 | ~8 | ~11.4 | ~22 | ~22.5 | ~49 | ~51 | |

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Rubber Mixing Mill

Mixing Mill

Rubber Mixing

Laboratory Mixing Mill

Two Roll Mixing Mill

Roll Mixing Mill

More>>